AMMETIS : AI-assisted Simulations of Microstructure driven MEchanical properties from high Throughput and multiscale analysIS.

Coordinator: Nathalie GEY

LEM3 – Université de Lorraine- CNRS – Arts et Métiers

Keywords: Microstructure, mechanical properties, metal alloys, surfaces, interfaces, high-throughput characterization, in-situ testing, microscopy, nanoindentation, micromechanics, crystal plasticity models, gradient plasticity, homogenization, reduced models, artificial intelligence

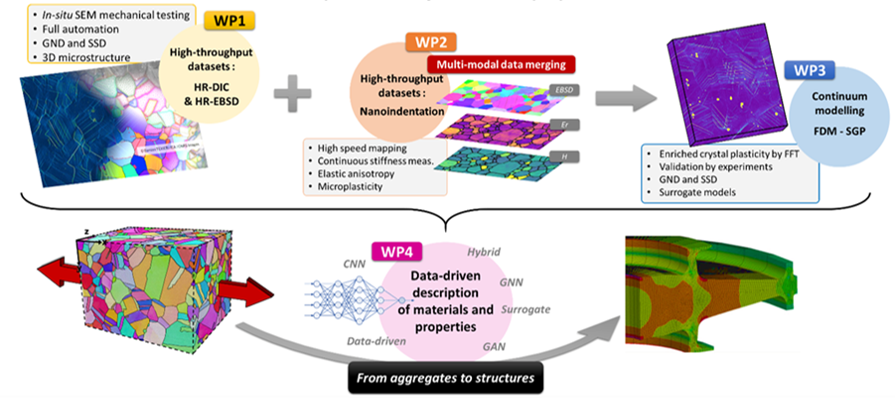

The AMMETIS project (AI-assisted Simulations of Microstructure driven MEchanical properties from high Throughput and multiscale analysIS) aims to accelerate our ability to reliably predict the in-service behavior of new material innovations proposed to meet the challenges of the energy transition.

This objective involves:

(1) Developing an experimental platform for high-throughput characterization at the mesoscopic scale (mechanical mapping by nanoindentation and high-resolution in-situ SEM image/EBSD correlation) to better understand the relationships between microstructures, deformation mechanisms, and macroscopic behavior in service.

(2) The development of innovative crystalline plasticity models (incorporating Dislocation Field Mechanics and Deformation Gradient Plasticity). These models will be enriched by experience to improve their predictive capabilities and applied to polycrystals via massively parallelized FFT calculations,

(3) The development of AI-based reduced models capable of predicting mechanical properties in real time based on knowledge of the microstructure, suitable for integration into structural calculations

This ambitious project brings together four national partners and is financially supported by two industrial partners (ArcelorMittal and SafranTech). In addition, it will be enriched by collaborations with two foreign laboratories engaged in similar challenges.

The methodologies will be optimized and validated on INCONEL718 as a model material, then implemented to better understand and predict the behavior of:

(1) third-generation steels produced using decarbonized processes, in order to further investigate the impact of residual elements on mechanical behavior in relation to microstructure (ARCELORMITTAL Maizières Research),

(2) materials with chemical composition and/or microstructure gradients in nickel-based superalloys with applications in the repair of structural parts, in particular (SafranTech).